The Construction Supply Chain

The construction supply chain refers to the interconnected network of organizations involved in the multiple processes and activities responsible for producing materials, components, and services required in the design, procurement, and delivery of a building. This supply chain involves various stakeholders, from suppliers of raw materials to contractors and subcontractors, all working together to bring a construction project to fruition.

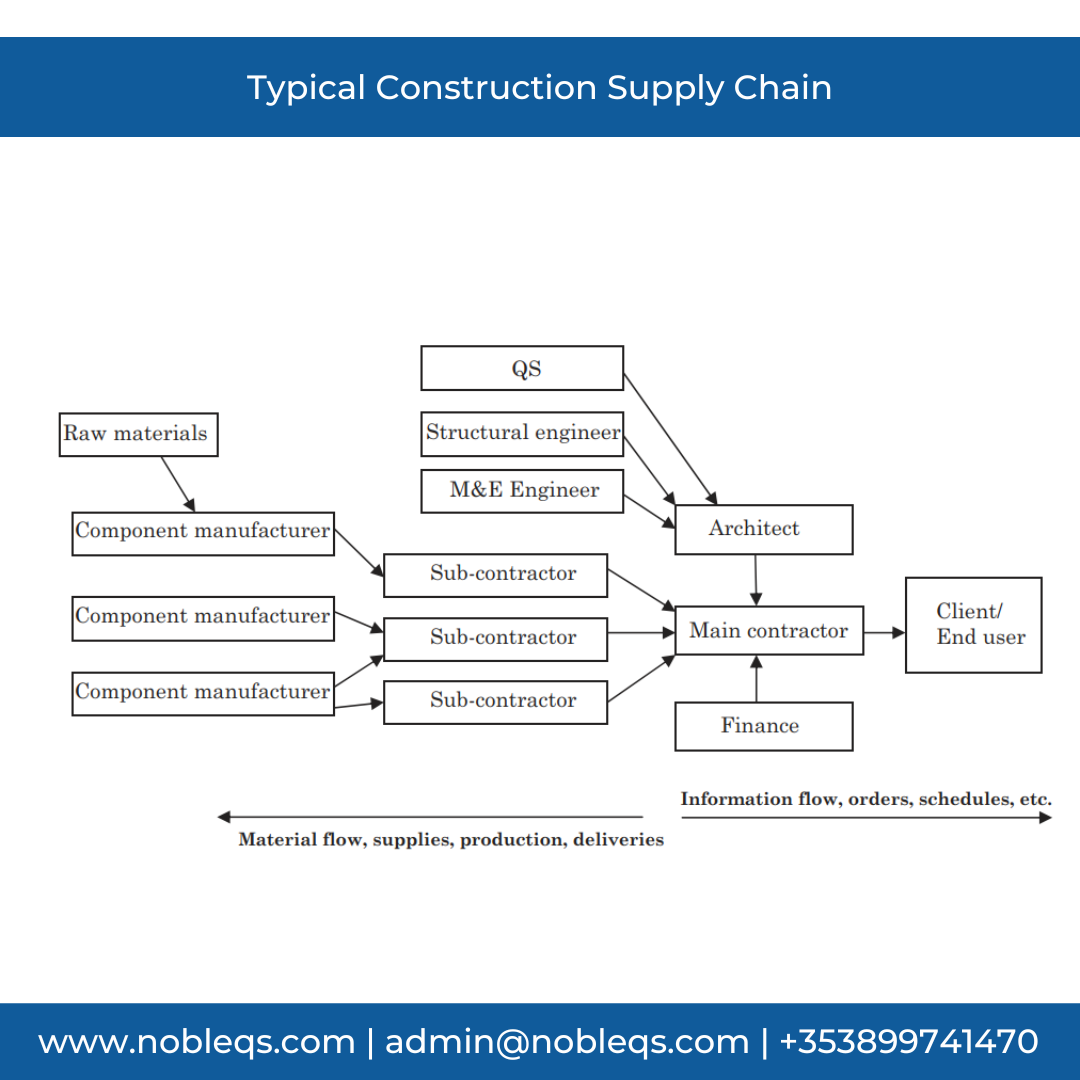

The diagram below provides a simplified representation of a typical construction supply chain. However, it's important to note that in reality, the supply chain can be much more complex, often involving numerous sub-contractors and specialized entities. The traditional supply chain approach in construction presents several challenges related to process control and improvement:

1.

Formation and Disbanding of

Temporary Alliances: In construction projects, different organizations

collaborate temporarily to complete a specific project. Once the project is

finished, these organizations disband and form new alliances for subsequent

projects. This constant reshuffling can lead to inefficiencies and difficulties

in maintaining consistent processes.

2. Communication Challenges: Effective communication of data, knowledge, and design solutions across the various organizations within the supply chain is crucial for smooth project execution. However, due to organizational boundaries, communication gaps can occur, leading to delays, errors, and misunderstandings.

3. Cross-Organizational Process Improvement: Improving processes that span multiple organizational boundaries becomes a challenge in the traditional supply chain model. Each organization may have its own priorities and strategies, making it difficult to achieve collective process improvements.

4. Aligning Goals and Objectives: As different organizations collaborate for a project, aligning their goals and objectives can be a complex task. Conflicting interests and priorities among stakeholders may hinder the smooth functioning of the supply chain.

5. Temporary Organization Improvement: Each organization involved in the supply chain may strive to improve its processes and practices independently. However, these improvements may not be effectively captured or shared among other organizations since the collaboration is temporary.

To address these challenges, construction companies and stakeholders are exploring alternative supply chain management approaches, such as integrated project delivery (IPD) and building information modeling (BIM). These methods emphasize collaboration, transparency, and shared responsibilities among all stakeholders, fostering a more cohesive and efficient construction supply chain. By aligning interests, promoting open communication, and encouraging knowledge sharing, construction projects can benefit from improved productivity, reduced delays, and enhanced overall project outcomes.

0 comments